Well wikipedia.com defines it as ... “printing technique that uses a woven mesh to support an ink-blocking stencil. The attached stencil forms open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edged image onto a substrate. A fill blade or squeegee is moved across the screen stencil, forcing or pumping ink into the mesh openings for transfer by capillary action during the squeegee stroke. Basically, it is the process of using a stencil to apply ink onto another material.” |

||||||

|

|

|||||

| Screen printings origins can be traced back the the Song Dynasty (960-1279 AD) in China. The simple stenciled screen has not changed. The advances can be found in how the screen and stencil are created, the squeegie process, multi color registration and the increase to production quality and quantity with the automatic presses. | ||||||

|

|

|

|

|

|

||

|

|

|

||||

Under basing is achieved when a white ink is used to print a base for a bright color to be visible and true to its desired color on a medium to dark colored garment. Do you have to under base? Yes. Below you will find a photo of red ink on a black t-shirt. There are areas with and with out under base. The brighter areas have a white ink under base. The white ink is printed and then flash cured to create a dry printable surface. The red ink is then printed on top. Almost all inks that are printed on medium to dark colored goods require under basing and flashing. |

||||

| Click this link to download a PDF of “Why Under Base?” to forward to you clients. | ||||

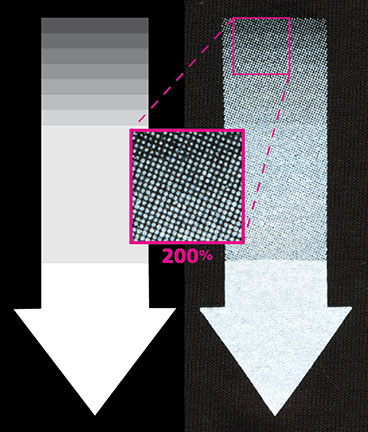

The simplest way to define halftones is the use of a series of small dots to emulate printing lower/lighter percentages of a color. Wikipedia.com defines it as: “Halftone is the reprographic technique that simulates continuous tone imagery through the use of dots, varying either in size, in shape or in spacing.” The best way is to describe halftones is to show you. Below is a pic of a white arrow with a gradient on a black back ground. The left arrow is what you would see in your virtual proof as it is displayed on your computer monitor. The right arrow is how it will look printed with halftones. |

||

|

||

The smooth greys of the left arrow are misleading. At a 60” distance the halfone dots would visually mix to appear more like the left arrow. At a closer look, the right arrow details the half tone dots and their roughness. Download a PDF of What are halftone dots? to forward to your clients. |

||

|

|

Why use halftones? Most often designers use halftones to make a 1 color print look like a multicolor. Sometimes its used for shading or glow effects. However halftones are esential to full color process and greyscale photographs and illustrations. Some issues/limitations to keep in mind when designing halftones to be used in screen printing: • A 20% difference in value is neede to show contrast between 2 halftoneareas. |

|